Systèmes de rails pour sacs de perforation

Buying Guide

A punching bag rail system (also known as a heavy bag track system) is one of the most effective ways to maximize floor space in a gym or home workout area. These systems allow you to slide heavy bags into position for training and tuck them away when the space is needed for other activities like HIIT, yoga, or grappling.

Types of Rail Systems

-

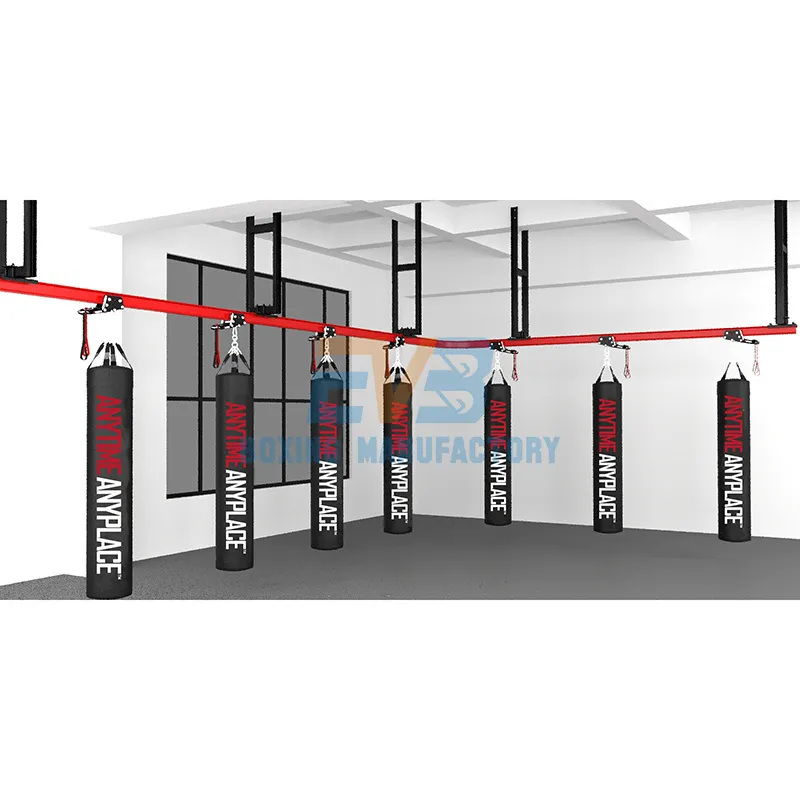

Ceiling-Mounted Rail System: These are the most common commercial solution. They feature a steel track bolted directly into ceiling joists or concrete. You can choose between linear tracks for straight runs or curved tracks to store bags flush against a wall or in a corner.

-

I-Beam Rolling Mounts: If your facility has exposed steel I-beams, these mounts clamp directly onto the beam flange. They are incredibly sturdy and usually offer the highest weight capacities.

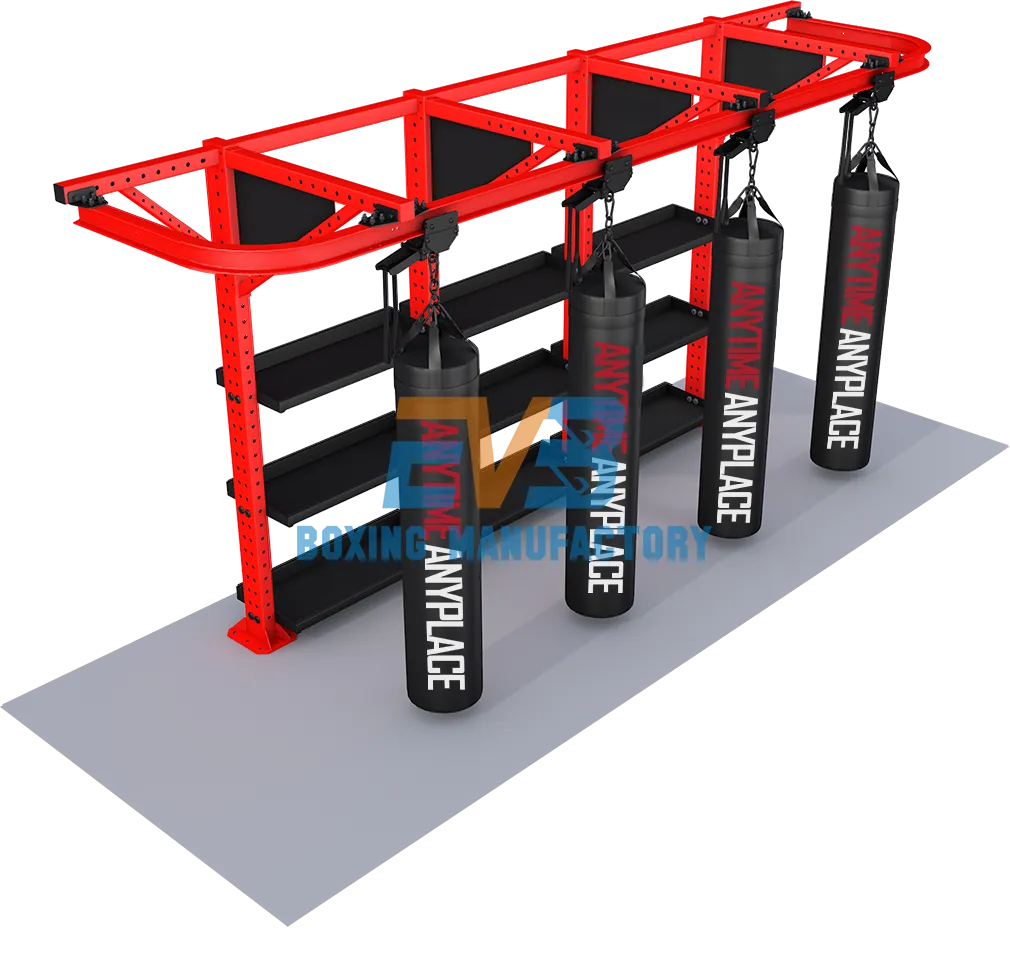

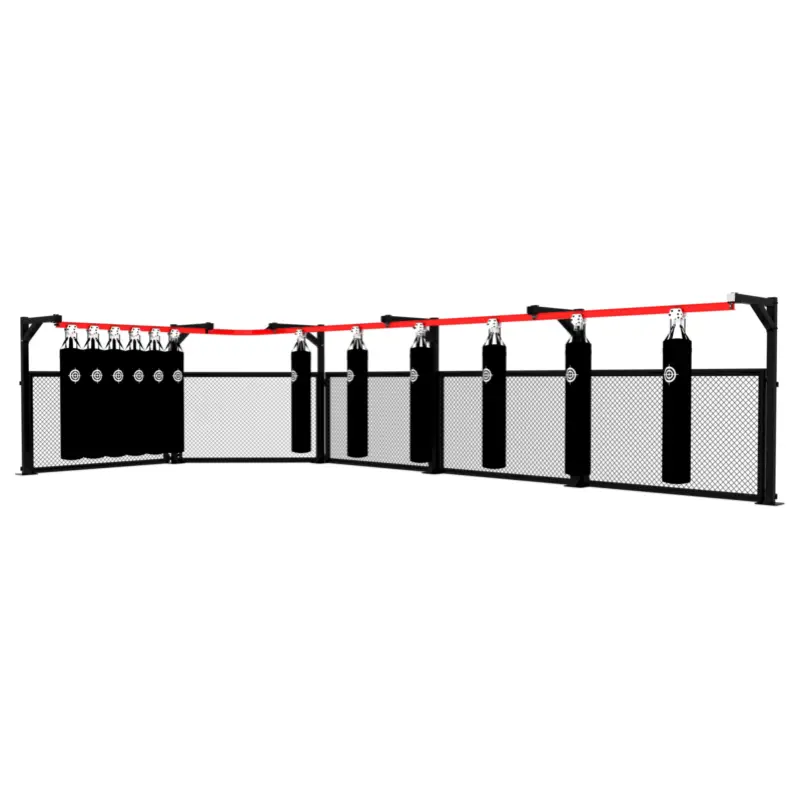

- Stand mounted Rail System: It is installed on the ground and can be combined with cage panels, and can be bent in any direction.

-

Modular Systems: These allow you to connect multiple 4-foot or 8-foot sections to create a custom-length rail that fits your specific room dimensions.

Critical Buying Factors

-

Dynamic Weight Capacity: A rail system must handle more than just the “dead weight” of the bag. Look for a system rated for at least 1.5x to 4x the weight of your bag to account for the force of your strikes. A standard 100lb bag should ideally be paired with a rail rated for 300lbs or more.

Installation & Maintenance Tips

-

Structural Support: Never mount a rail system to drywall alone. It must be anchored into structural wood joists, steel beams, or concrete.

-

Maintenance: Inspect all mounting bolts weekly for any signs of loosening due to vibration. Lubricate the trolley bearings quarterly with a dry silicone spray to prevent “stuttering” along the track.

-

Spacing: When installing, leave at least 6 feet of clearance around the bag’s training position to allow for a full 360-degree swing and safe footwork.

FAQs

Can I install a heavy bag rail system on a standard drywall ceiling?

No. Rails must be anchored directly into structural wood joists, steel I-beams, or concrete. For finished ceilings, you will need a system compatible with 12, 16, or 24 on-center joist spacing.

How many heavy bags can one rail system hold?

This depends on the rail length and your building’s structural integrity. Typically, we recommend one bag every 1.5m of rail to prevent collisions and allow for full 360-degree movement around the bag.

Can I use different types of bags on the same rail?

Absolutely. Our trolleys are compatible with standard heavy bags, Muay Thai long bags, teardrop bags, and even aqua bags.

Are you a real manufacturer?

Yes, we are the source Punching Bag Rail System manufacturer, we are located in Shenzhen, China, you are welcome to visit our factory.

How long is the production time?

Usually we will complete production in 15-30 days

What shipping method do you use?

Depends on trade terms (such as EXW\FOB\CIF\DDU\DDP), usually we use sea shipping to transport products, we also provide door-to-door service, reducing your work.